Cara Memilih Pellet Mill Die untuk Kinerja Pelletizing yang Optimal

2025-12-29

.gtr-pellet-dies-comp-9876 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

line-height: 1.6;

padding: 20px;

max-width: 100%;

box-sizing: border-box;

}

.gtr-pellet-dies-comp-9876 .gtr-title {

font-size: 18px;

font-weight: bold;

margin-bottom: 20px;

color: #0056b3;

text-align: left;

}

.gtr-pellet-dies-comp-9876 .gtr-section-title {

font-size: 18px;

font-weight: bold;

margin-top: 30px;

margin-bottom: 15px;

color: #0056b3;

text-align: left;

border-bottom: 1px solid #eee;

padding-bottom: 5px;

}

.gtr-pellet-dies-comp-9876 p {

font-size: 14px;

margin-bottom: 15px;

text-align: left !important;

word-break: normal;

overflow-wrap: normal;

}

.gtr-pellet-dies-comp-9876 p strong {

color: #0056b3;

}

.gtr-pellet-dies-comp-9876 ul {

list-style: none !important;

padding-left: 20px !important;

margin-bottom: 15px;

}

.gtr-pellet-dies-comp-9876 ul li {

position: relative;

padding-left: 20px;

margin-bottom: 8px;

font-size: 14px;

text-align: left;

list-style: none !important;

}

.gtr-pellet-dies-comp-9876 ul li::before {

content: "•" !important;

position: absolute !important;

left: 0 !important;

color: #0056b3;

font-size: 18px;

line-height: 1;

top: 0;

}

.gtr-pellet-dies-comp-9876 ul li strong {

color: #0056b3;

list-style: none !important;

}

.gtr-pellet-dies-comp-9876 .gtr-contact-info {

font-size: 14px;

margin-top: 20px;

text-align: left !important;

}

.gtr-pellet-dies-comp-9876 .gtr-contact-info a {

color: #0056b3;

text-decoration: none;

}

.gtr-pellet-dies-comp-9876 .gtr-contact-info a:hover {

text-decoration: underline;

}

@media (min-width: 768px) {

.gtr-pellet-dies-comp-9876 {

padding: 30px 40px;

max-width: 900px;

margin: 0 auto;

}

.gtr-pellet-dies-comp-9876 .gtr-title {

font-size: 18px;

margin-bottom: 25px;

}

.gtr-pellet-dies-comp-9876 .gtr-section-title {

font-size: 18px;

margin-top: 40px;

margin-bottom: 20px;

}

.gtr-pellet-dies-comp-9876 p {

margin-bottom: 20px;

}

.gtr-pellet-dies-comp-9876 ul {

padding-left: 25px !important;

}

.gtr-pellet-dies-comp-9876 ul li {

padding-left: 25px;

margin-bottom: 10px;

}

.gtr-pellet-dies-comp-9876 ul li::before {

font-size: 20px;

}

}

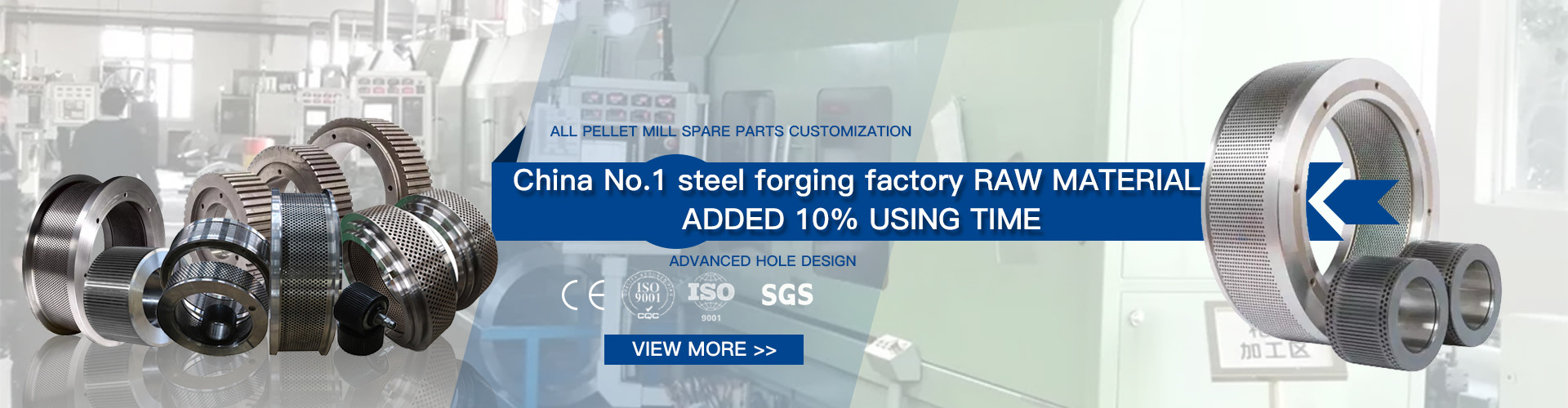

Mata Die Pabrik Pelet Berkualitas Tinggi untuk Kinerja Pelletizing Optimal

Sebagai produsen terkemuka mata die pabrik pelet berkinerja tinggi, kami mengkhususkan diri dalam memproduksi die pelet kustom dan standar yang kompatibel dengan merek pabrik pelet utama, termasuk CPM, SZLH, PTN, Bühler, dan banyak lagi. Baik Anda terlibat dalam pakan ternak, biomassa, atau produksi pupuk organik, mata die pelet kami direkayasa untuk memberikan efisiensi, daya tahan, dan konsistensi maksimum.

Apa itu Mata Die Pabrik Pelet?

Mata die pabrik pelet adalah komponen penting dalam proses pelletizing. Ini adalah cincin atau pelat datar yang direkayasa presisi dengan lubang, yang melaluinya bahan bubuk dikompresi dan dibentuk menjadi pelet seragam. Die bekerja bersama dengan rol untuk memberikan tekanan dan panas, membentuk pelet padat dan padat yang ideal untuk transportasi, penyimpanan, dan pemberian pakan.

Kemampuan Mata Die Pelet Kami

Kami dilengkapi untuk memproduksi die sesuai spesifikasi yang tepat, memastikan kompatibilitas dan kinerja yang optimal. Kemampuan kami meliputi:

Manufaktur Kustom (berdasarkan gambar atau sampel)

Die Standar untuk model pabrik pelet utama

Pemilihan Bahan (misalnya, baja tahan karat, baja paduan)

Ukuran Lubang Bor dari 1.0 mm hingga 12.0 mm

Rasio Kompresi yang disesuaikan dengan bahan baku dan aplikasi Anda

Merek Pabrik Pelet yang Kompatibel

Kami memproduksi die pengganti dan kustom untuk berbagai model pabrik pelet, termasuk:

CPM

SZLH

PTN

Bühler

Dan merek internasional populer lainnya

Semua die diuji dan diperiksa sepenuhnya untuk akurasi dimensi, kekerasan, dan hasil akhir permukaan.

Mengapa Memilih Mata Die Pelet Kami?

Rekayasa Presisi: Die yang dikerjakan CNC memastikan keluaran tinggi dan kualitas pelet yang konsisten.

Solusi Kustom: Rasio kompresi dan bahan yang disesuaikan untuk bahan baku yang berbeda (jagung, alfalfa, dedak gandum, dll.).

Umur Pakai yang Panjang: Dibuat dari bahan tahan aus dan diberi perlakuan panas untuk daya tahan.

Pengiriman Cepat: Produksi dan logistik yang efisien untuk pengiriman tepat waktu di seluruh dunia.

Dukungan Teknis: Konsultasi ahli untuk pemilihan die dan optimasi pabrik pelet.

Aplikasi

Mata die pelet kami banyak digunakan dalam:

Produksi Pakan Ternak (unggas, ternak, domba, ikan)

Pelletizing Biomassa (kayu, jerami, sekam padi, dll.)

Pelet Pupuk Organik

Pelletizing Limbah Industri dan Pertanian

Hubungi Kami Hari Ini

Mencari mata die pabrik pelet berkinerja tinggi yang andal? Bermitra dengan kami untuk solusi yang disesuaikan dan kualitas tak tertandingi. Kirimkan sampel, gambar, atau spesifikasi Anda, dan kami akan memproduksi die yang sangat sesuai dengan kebutuhan Anda.

Email: apexbiomass0909@gmail.comTelepon: [wa/line : +86- 18562307530]

Lihat Lebih Banyak

Prospek Pasar Global untuk Industri Mesin Pellet Biomass Mill

2025-12-24

.gtr-container-x7y2z9 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

line-height: 1.6;

padding: 15px;

box-sizing: border-box;

width: 100%;

max-width: 100%;

overflow-x: hidden;

}

.gtr-container-x7y2z9-title {

font-size: 18px;

font-weight: bold;

margin-bottom: 20px;

text-align: left;

color: #0056b3;

}

.gtr-container-x7y2z9 p {

font-size: 14px;

margin-bottom: 15px;

text-align: left !important;

line-height: 1.6;

color: #444;

}

.gtr-container-x7y2z9 p:last-child {

margin-bottom: 0;

}

.gtr-container-x7y2z9 strong {

font-weight: bold;

color: #000;

}

@media (min-width: 768px) {

.gtr-container-x7y2z9 {

padding: 30px;

}

.gtr-container-x7y2z9-title {

margin-bottom: 25px;

}

.gtr-container-x7y2z9 p {

margin-bottom: 20px;

}

}

Prospek Pasar Global untuk Industri Mesin Pellet Biomass Mill

Pasar global untukMesin penggilingan pellet biomassamengalami pertumbuhan yang stabil, didorong oleh kebijakan energi terbarukan dan meningkatnya biaya energi.sementara pasar Amerika Utara dan Asia-Pasifik berkembang pesat.

Pabrik pelet yang berorientasi ekspor mengandalkan Mesin Biomass Pellet Mill berkapasitas tinggi untuk memenuhi standar kualitas internasional.dan konsistensi ukuran adalah faktor penting untuk perdagangan global.

Produsen semakin menawarkan solusi yang disesuaikan berdasarkan jenis bahan baku, kapasitas produksi, dan peraturan energi lokal.Fleksibilitas ini membuat peralatan pelet biomassa dapat disesuaikan dengan beragam kebutuhan pasar.

Karena investasi energi terbarukan meningkat di seluruh dunia, Mesin Biomass Pellet Mill diperkirakan akan tetap menjadi teknologi kunci yang mendukung produksi energi berkelanjutan dan perlindungan lingkungan.

Lihat Lebih Banyak

Mesin Pabrik Pelet Biomassa Mendukung Peningkatan Permintaan Bahan Bakar Pemanas Bersih

2025-12-24

Mesin Pabrik Pelet Biomassa Mendukung Peningkatan Permintaan Bahan Bakar Pemanas Bersih

Permintaan akan bahan bakar pemanas bersih terus meningkat, terutama di Eropa dan Amerika Utara. Mesin Pabrik Pelet Biomassa memainkan peran sentral dalam memenuhi permintaan ini dengan memungkinkan produksi pelet skala besar.

Pelet biomassa banyak digunakan dalam kompor pelet perumahan, sistem pemanas distrik, dan boiler industri. Ukuran yang konsisten dan kepadatan tinggi mereka memungkinkan pengumpanan otomatis dan pembakaran yang efisien.

Pabrik pelet yang dirancang untuk penggunaan industri dapat beroperasi 24/7 dengan waktu henti minimal. Sistem pendingin, unit pengumpul debu, dan peralatan penyaringan pelet sering diintegrasikan ke dalam lini produksi yang lengkap.

Dengan meningkatnya pembatasan penggunaan batu bara dan bahan bakar fosil, pelet biomassa menjadi alternatif yang lebih disukai. Akibatnya, investasi dalam Mesin Pabrik Pelet Biomassa terus meningkat di seluruh pasar global.

Lihat Lebih Banyak

Kemajuan Teknologi Meningkatkan Efisiensi Mesin Biomass Pellet Mill

2025-12-24

Kemajuan Teknologi Meningkatkan Efisiensi Mesin Biomass Pellet Mill

Inovasi terus menerus telah secara signifikan meningkatkan kinerjaBiomass Pellet Mill MesinPada tahun-tahun belakangan ini, para produsen sekarang fokus untuk meningkatkan output, mengurangi konsumsi energi, dan memperpanjang umur peralatan.

Salah satu kemajuan utama adalah penggunaan baja paduan kekuatan tinggi untuk mati dan rol. Hal ini meningkatkan ketahanan keausan dan memungkinkan mesin untuk beroperasi di bawah beban berat untuk jangka waktu yang lama.Sistem pelumasan otomatis mengurangi kebutuhan pemeliharaan.

Sistem kontrol cerdas juga menjadi standar. Operator dapat memantau suhu, tekanan, dan beban motor secara real time, memastikan operasi yang stabil dan kualitas pelet yang konsisten.Sistem ini mengurangi waktu henti dan meningkatkan efisiensi produksi secara keseluruhan.

Efisiensi energi adalah peningkatan utama lainnya. Sistem transmisi yang dioptimalkan dan drive frekuensi variabel membantu mengurangi konsumsi daya per ton pelet yang diproduksi.

Berkat inovasi ini, Mesin Biomass Pellet Mill sekarang lebih andal dan hemat biaya, membuatnya cocok untuk pabrik industri skala besar dan operasi biomassa berukuran menengah.

Lihat Lebih Banyak

Mengapa Mesin Pabrik Pelet Biomassa Penting untuk Daur Ulang Limbah Pertanian

2025-12-24

Mengapa Mesin Penggiling Pelet Biomassa Penting untuk Daur Ulang Limbah Pertanian

Pengelolaan limbah pertanian telah menjadi tantangan utama di seluruh dunia. Mesin Penggiling Pelet Biomassa menawarkan solusi efektif dengan mengubah residu tanaman menjadi bahan bakar terbarukan yang berharga.

Bahan-bahan seperti batang jagung, jerami gandum, sekam padi, dan cangkang bunga matahari sering dibuang atau dibakar di ladang terbuka. Dengan menggunakan Mesin Penggiling Pelet Biomassa, bahan-bahan ini dapat diproses menjadi pelet biomassa yang cocok untuk pemanas industri dan perumahan.

Proses peletisasi mengurangi volume material sekaligus meningkatkan kepadatan energi. Hal ini membuat transportasi dan penyimpanan lebih efisien dan mengurangi polusi lingkungan. Petani dan pengolah biomassa juga dapat menghasilkan pendapatan tambahan dengan mengubah limbah menjadi produk yang dapat dipasarkan.

Mesin Penggiling Pelet Biomassa canggih dirancang untuk menangani kadar air yang bervariasi dan bahan baku campuran. Rol yang diperkuat dan desain cetakan yang dioptimalkan memastikan pembentukan pelet yang stabil bahkan saat memproses biomassa pertanian yang menantang.

Dengan meningkatnya minat pada model ekonomi sirkular, produksi pelet biomassa menjadi penghubung penting antara pertanian dan industri energi terbarukan.

Lihat Lebih Banyak